According to the Washington State Department of Labor & Industries, ladder safety is crucial for preventing workplace injuries and complying with safety regulations. This guide covers key aspects of ladder safety, including proper selection, safe usage practices, and training requirements, based on OSHA standards and state-specific regulations.

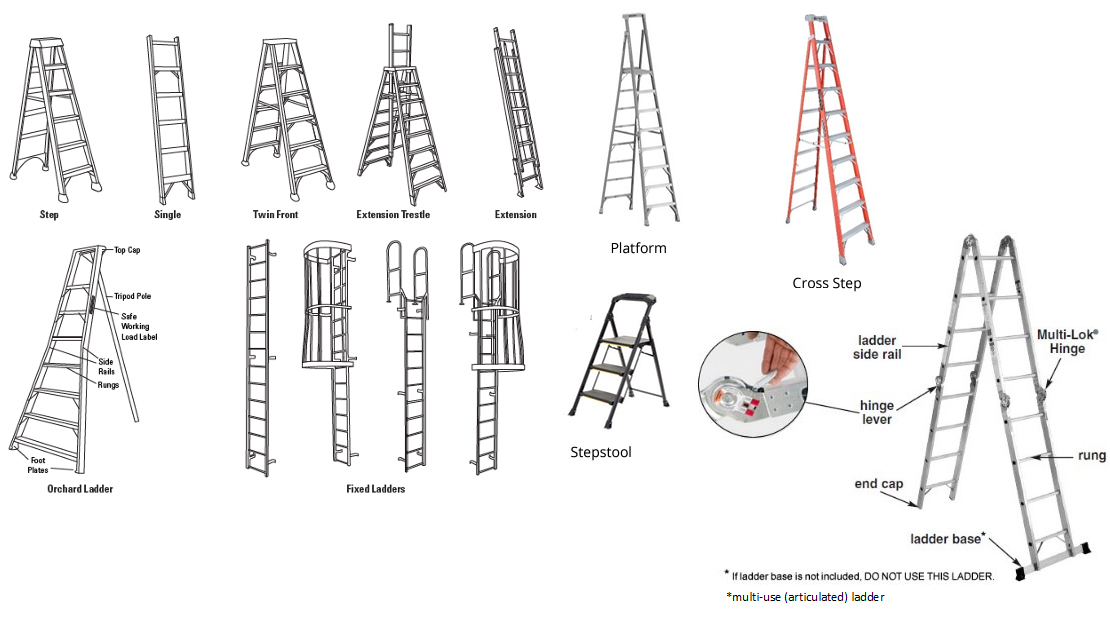

Types of Ladders

Ladders come in various types, each designed for specific purposes and work environments. Below is a list of some of the most common types of ladders you can see at your workplace.

- Straight Ladder – A ladder that you can lean against a surface, such as a house, which supports the ladder.

- Extension Ladder – An extension ladder is a straight ladder that has another ladder attached to it allowing you to go higher. They require additional maintenance.

- A-frame, Step or Self-supporting Ladders – These ladders support themselves and can be set up away from walls, etc.

- Fixed Ladders - A ladder permanently attached to a building or structure. These least likely to shift/fall during use and often do not require anyone to carry it or set it up.

- Orchard Ladders – These have only 3 legs and mostly used to gain access inform soft soil up to typically fruit-bearing trees.

- Multi-Use Ladders (Articulated) – These are the most versatile. They can function as a stepladder, an extension ladder, or turned into a scaffold. However, the ladders are often heavy and expensive.

- Job Built Ladders – Mostly on construction sites, these need to be approved by a professional engineer and are built for a specific job and then destroyed when done.

General Safety Guidelines

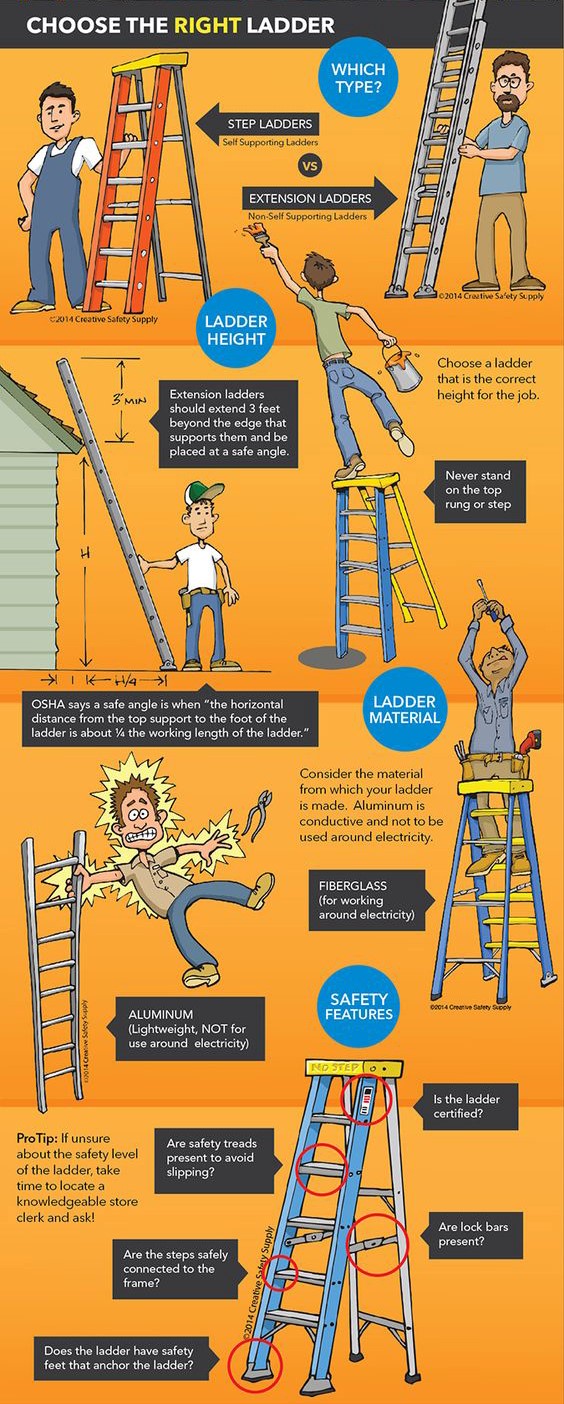

When using ladders, maintaining THREE POINTS of contact (two hands and one foot, or two feet and one hand) is crucial for stability and safety. Always face the ladder while climbing or descending, and keep your body centered between the side rails. Avoid carrying tools or materials in your hands; instead, use a tool belt or raise equipment using a hand line. A good rule of thumb: keep your belt buckle between the rails.

- Never exceed the ladder’s maximum load rating, which includes your weight plus any tools or materials.

- For extension ladders ensure the ladder extends at least 3 feet above the upper landing surface when accessing elevated area.

- Place ladders on stable, level surfaces and secure them at the top and bottom when possible.

- Never stand on the top step or cap of a step ladder, as this is extremely dangerous and unstable.

- Keep the area around the top and bottom of the ladder clear of trip hazards and potential obstructions.

- Avoid overreaching or leaning to the side, which can cause the ladder to tip over.

- Select the appropriate ladder material and ensure it has the correct rating for your specific type of work.

- Read the safety information labels on the ladder for proper set up.

By following these general safety guidelines, workers can significantly reduce the risk of ladder-related injuries and create a safer work environment. (*this does not cover ladder safety training)

Choosing a fiberglass, aluminum or wood ladder?

- Fiberglass - this material is durable, weather resistant, non-conductive and does not need the same maintenance that wood ladders need. But it is heavy, can chip and crack when not handled properly, and is damaged by exposure to UV light like sunlight or welding spark.

- Wood - this material provides good insulation from heat/cold and feel natural when climbing but, they require additional maintenance and are heavy.

- Aluminum - these are lightweight and corrosion resistant but are dangerous when working around electricity.

Select the Right Ladder

Choosing the appropriate ladder is crucial for ensuring safety and efficiency in the workplace. When selecting a ladder, consider the following key factors:

- Height: Determine the required reach height for the task and choose a ladder that extends at least 3 feet above the landing surface

- Material: Select fiberglass ladders for electrical work to prevent conductivity, while aluminum ladders are suitable for lightweight applications.

- Duty rating: Choose a ladder with the appropriate weight capacity to support the user’s weight plus any tools or materials.

- Type: Decide between stepladders, extension ladders, or fixed ladders based on the specific job requirements.

- Environmental conditions: Consider factors such as uneven ground, slippery surfaces, or potential electrical hazards

Inspections

- Every ladder user needs to inspect the ladder before they use it for the day.

Training Requirements

Employers are responsible for providing training to employees on ladder safety. Contact EHS to assign Ladder Safety training on HSI, this is the preferable option.

- Ladder Training is annual

- Employees whose job requires them to use a ladder

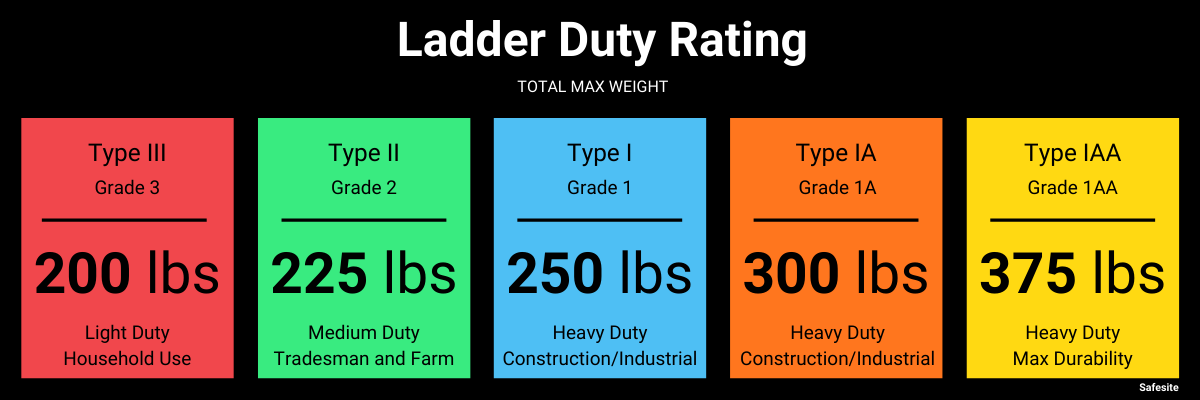

Ladder Rating

Ladder Rating - ratings are based on weight capacity (worker + equipment)

- Type IAA (Extra Heavy Duty) = 375 lbs

- Type IA (Extra Heavy Duty) = 300 lbs

- Type I (Heavy Duty) = 250 lbs

- Type II (Medium Duty) = 225 lbs

- Type III (Light Duty) = 200 lbs (not recommended)

- Label must always be attached to ladder

Ladder Safety Training Videos

Ladder Safety Materials

- OSHA’s Ladder Safety DOS and DON’Ts

- Ladder Safety Training - General Ladder Use (PDF) PowerPoint training: fill out Ladder Inspection Training Form & email copy to EHS

- Ladder Inspection Training Form (PDF)

- L&I’s 10 Tips for Ladder Safety (PDF)

- L&I Ladder Safety Guide (PDF)

- Ladder Safety Checklist (PDF)