Since the COVID-19 pandemic began its domination of the global news cycle in February, the virus has served as a framework around which to discuss a host of other topics. One of the most notable: the shortcomings of the American health care system, specifically the limited number of ventilators. In March, the American Hospital Association estimated that up to 960,000 Americans could become sick enough to require ventilation—but the United States only had about 200,000 machines.

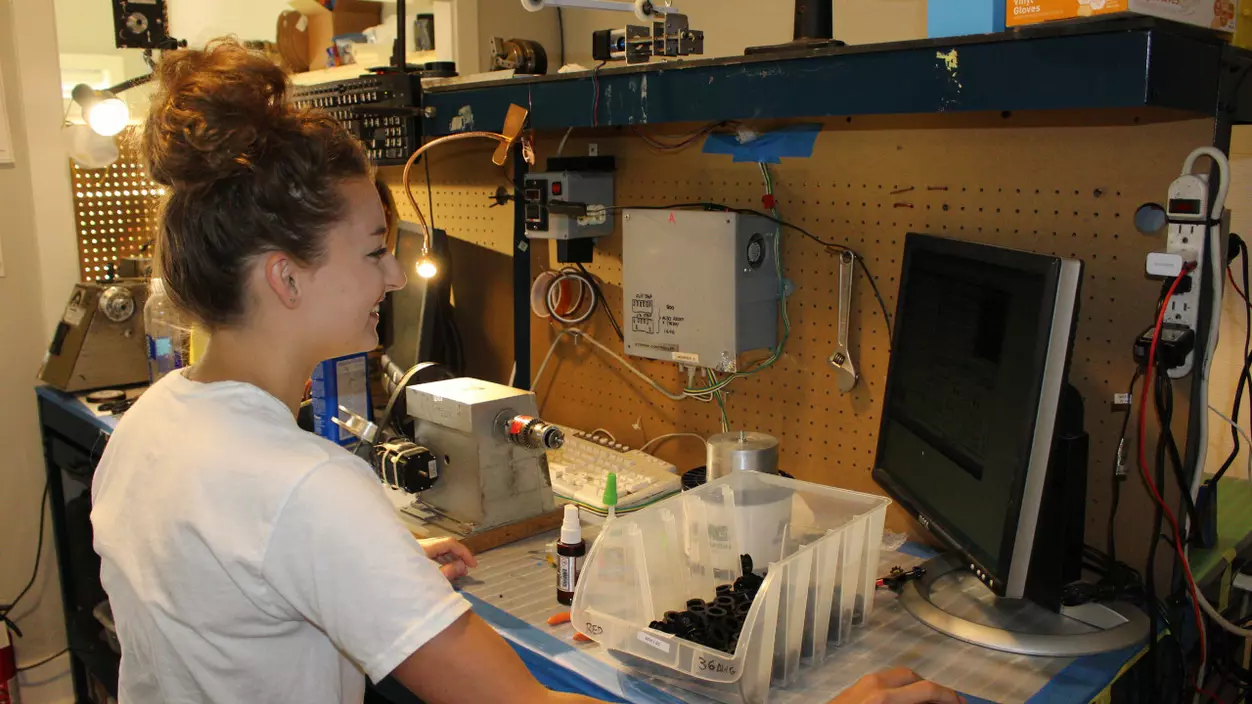

Ventilators have become the last-resort treatment for the most critically ill COVID-19 patients. Also known as breathing machines, ventilators consist of a series of valves and pumps which create circuits that blow air into and pull air out of the lungs. Those valves are controlled by a device called a voice coil actuator—a copper coil with magnets contained inside a metal housing—that opens and closes the valves. And some of those actuators are made in a small, unassuming home business half a mile from the Puget Sound campus with help from international political economy student Emma McAllister ’20.